Belleville, Ontario Canada

Our composting process uses state-of-the-art technology and methods, and produces virtually no odour or harmful emissions.

Our composting process uses state-of-the-art technology and methods, and produces virtually no odour or harmful emissions.

SusGlobal Energy Belleville is committed to having good two-way communication lines with area residents, local businesses and all governing bodies to ensure the SusGlobal Energy site is the best in class.

704 Phillipston Road

Belleville, Ontario, Canada, K0K 2Y0

Telephone: 613-477-2424

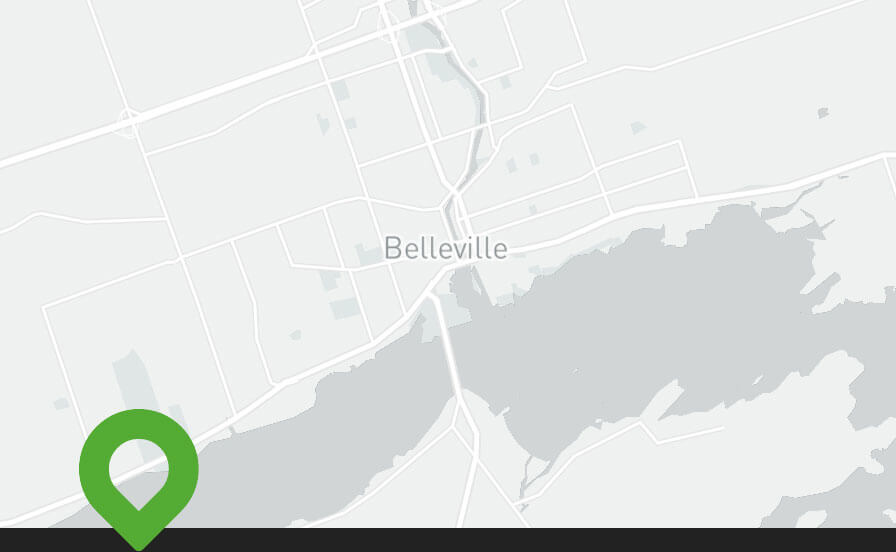

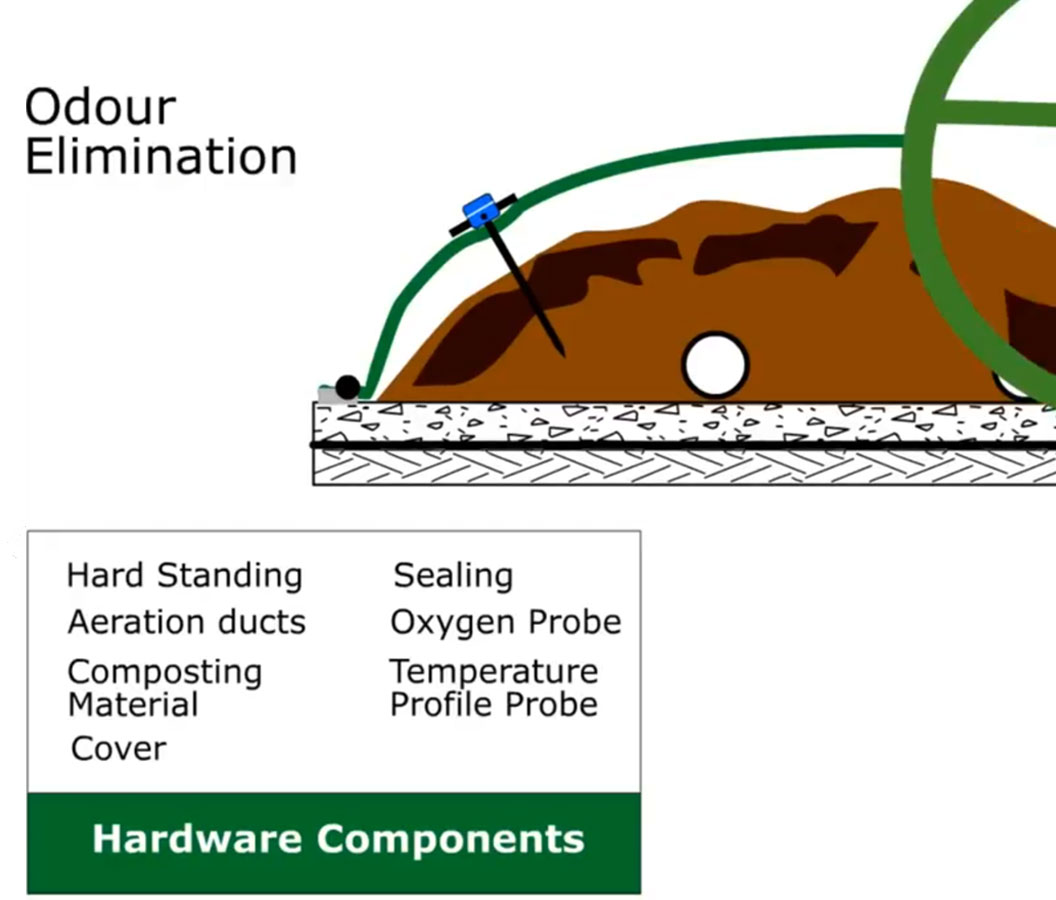

SusGlobal Energy has chosen the state of the art GORE® Cover System as its operating platform. Using the technology created by W.L. Gore and Associates, the Belleville processing facility can transform green waste into high quality compost in a period of only 8 weeks. With minimal emissions and virtually no odour, SusGlobal Energy offers a sustainable and environmentally friendly solution to disposing of green waste.

The GORE® Cover System utilizes positive aeration and a specially designed cover to create an enclosed system that optimizes the composting process, controls odors and micro-organisms, separates leachate from storm water and creates a consistent process unaffected by outside environmental conditions. Medium-pressure ventilators connect to in-floor aeration trenches, which allows oxygen to be blown into the heap. Stainless steel probes inserted into the compost pile monitor oxygen and temperature parameters, then relay this information to a central computer. This data then controls ventilators to keep the compost in the perfect conditions.

The design of the GORE® Cover influences the extraction of moisture during composting and prevents the final product from being too wet, while at the same time ensures that there is sufficient moisture retained to allow the material to be properly decomposed. The microporous structure of the GORE® Cover membrane means that it is practically impossible for bio-aerosols to penetrate. Microbiological tests have proved that when using the GORE® Cover, microbes can be reduced by greater than 99%; thus ensuring that workers, nearby residents and consumers are protected and safe . The insulating effect of the GORE® Cover and the pressurization created ensures even temperature distribution, which mean that the necessary temperature for pathogen reduction across the entire cross-section of the heap can be maintained, even during the winter months. By closely monitoring and managing temperature within the heap, pathogenic micro-organisms are safely destroyed throughout the entire composting material and all quality standards are met.

Incoming material to the facility will be blended with other organic material to create the perfect “recipe” for the composting process. This blending includes setting the mixture’s moisture content, carbon-to-nitrogen ratio, particle size and porosity. Once the blending is complete, the material is moved into windrows and the GORE® Cover is pulled over the pile for the first phase of the composting process. For the next four weeks, the windrow undergoes intensive composting until the cover is removed and the windrow is moved into Phase 2 of the system. The windrow is covered again for maturation for a period of a further two weeks. After this time, the compost is moved to Phase 3 where it is left uncovered on an aerated pad for an additional 2 weeks to begin the curing process. Once removed from Phase 3, the compost will continue curing in large storage windrows before it is screened to the appropriate particle size.

Before finished compost is sold, samples are taken and sent to an accredited lab to ensure that the product quality is consistent with Ontario Regulation. These lab tests will measure certain levels within the compost including: heavy metals, fecal coliform and salmonella. In addition to the required testing, we also test all of our product for nutrient content including nitrogen, phosphorus, potassium and sodium to ensure the utmost quality for our consumers. It is only when test results have confirmed that the finished product meets all requirements both by law and by our own standards that the all natural fertilizer will be marketed to our customers.

The high quality compost produced at the Belleville facility has a number of uses and benefit. High quality compost has been proven to enhance the physical, chemical and biological properties of a soil. When applied to coarse textured soils, the compost allows for increased nutrient and water retention and when applied to heavy textured soils, the compost will improve the soil structure, infiltration and drainage. Also, the addition of compost to a soil will increase the organic material content and significantly enhance the rate of biological activity.

Finished compost is primarily used in the agricultural industry as an alternative to chemical substances but it is also used by landscapers and home gardeners to enhance soil and by engineers and contractors to control erosion and runoff.

Some of the other benefits of compost use are:

- Improved soil tilth and structure

- Improved water holding capacity of sandy soils

- Improved drainage in heavy soils

- Improved holding capacity of soil nutrients

- Prevention of or decreased erosion

- Improved soil aeration

- Reduced need for chemical fertilizers

- Remediation of chemically damaged soils

- Replenishment of trace and macronutrient stores

- Increased activity of microorganisms within the soil

- Reduced incidence or severity of certain soil-borne diseases

- Reduced pesticide use

SusGlobal Energy offers mobile grinding services for a variety of residential and commercial clients. With our state of the art equipment, we are able to provide grinding services for all types of wood waste including brush, construction waste, railroad ties, logs and more. We are also able to process plastics and asphalt shingles into a useable product. Our mobile grinding service is ideal for land clearing and large development projects as it provides a fast and effective way to remove debris from the site.

By grinding waste and debris, we are conforming to our philosophy of landfill diversion. Grinding material on-site not only allows us transform waste into a useable product for our customer, but allows us to process debris that can then be recycled in an environmentally friendly manner instead of sending it to the landfill.

SusGlobal Energy also offers custom mulch manufacturing services as well as the sale of landscaping mulch of all colours. Depending on our customers’ needs, we have the equipment and ability to manufacture high quality mulch to exact colour and size specifications. Interchangeable screens coupled with an all in one grind-and-colour system, gives us the versatility and efficiency to meet the precise needs of our clients.

SusGlobal Energy offers mobile screening services for a variety of residential and commercial clients. With our state of the art equipment, we are able to provide screening services for your topsoil, sand, wood chips, compost and garden debris.

By removing excess material and debris, we are conforming to our philosophy of landfill diversion. Screening material on-site not only allows us to leave our customers with a product they can use, but we are also able to pull out and collect excess material to be recycled instead of sending it to the landfill.

SusGlobal Energy also offers custom soil blending services as well as the sale of unique blended soils. Depending on our customers’ needs, we have the equipment and ability to manufacture high quality soil to exact organic matter and water conductivity specifications. From golf course blends, to landscaping soils, SusGlobal Energy has the solution for virtually all soil needs.

SusGlobal Energy Belleville is committed to having good two-way communication lines with area residents, local businesses and all governing bodies to ensure the SusGlobal Energy site is the best in class. A Public Liaison Committee (PLC) is being developed to assist with our corporate transparency philosophy and ensure our communities have a voice and knowledge of site operations. The committee will be comprised of area residents, business, SusGlobal Energy management staff, and Non-Government Organizations. We feel the PLC will give an opportunity to SusGlobal Energy to communicate business aspects for the site to our community as well a chance for our community to ensure they understand operational details. For Terms of Reference for the PLC, please click the link below.

All necessary approvals are in place at the SusGlobal Energy Belleville site. An existing Provisional Certification of Approval (C of A) for a Waste Disposal Site (2010) is in place on the property that allows for the transfer and processing of non-hazardous recyclable materials, solid non-hazardous municipal waste and leaf and yard waste from domestic and commercial sources. The site has a C of A to include food waste and other materials for composting.

Three Environmental Compliance Approvals (ECA) from the Ministry of the Environment and Climate Change are now in place on the site:

- Amended Environmental Compliance Approval No. 0031-7UTRSS, dated August 7, 2015 for a Waste Disposal Site under Section 27 of the Environmental Protection Act;

- Environmental Compliance Approval No. 0565-9WXGBY, dated August 7, 2015 for Air and Noise for a Waste Disposal Site under Section 9 of the Environmental Protection Act; and

- Environmental Compliance Approval No. 5515-9VEL3J, dated August 10, 2015 for Sewage for a Waste Disposal Site under Section 53 of the Ontario Water Resources Act.

Content